SKID STEER ATTACHMENTS

SKID STEER MOUNT HYDRAULIC BREAKER

Absolute superiority is the only way to describe this breaker!

We here at Blue Diamond® have completed our 5 year quest to develop our superior Hydraulic Breaker for skid steers. This “hammer” design offers technology, simplicity, reliability, ease of setup, and service support. Our hydraulic breaker has little to no downtime. Get started on your demolition, construction, and quarry jobs today!

Product Details

Download Brochure- 3-year warranty

- Mono-block design / no tie rods

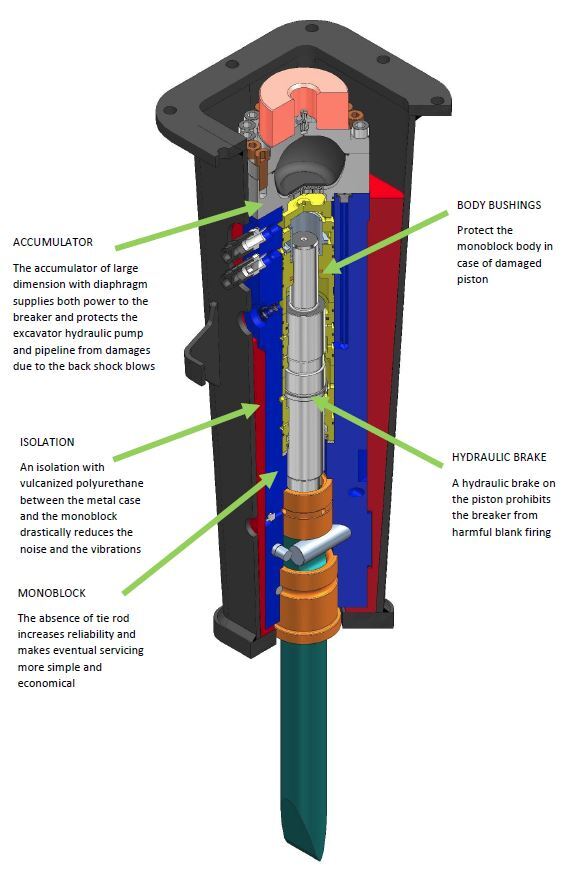

- Anti-blank firing system hydraulic brake

- No re-gassing needed

- Only 2 internal moving parts

- 2 speed control / variable stroke

- Quiet operation

- Self-regulating

- Body bushings around piston

Blue Diamond Attachments offers key differentiators that add performance and value to skid steer breaker attachments

- Blue Diamond skid steer breakers combine engineering excellence with practical design features to increase productivity and minimize maintenance costs.

- Blue Diamond backs its skid steer hydraulic breaker with exceptional service support and parts inventory.

- All Blue Diamond breakers are engineered with practical features that enhance durability, for longer product life.

Blue Diamond offers three tools for the hydraulic breakers to correspond with specific breaking requirements.

The moil point tool features a conical tip designed for concentrated breaking force at a single point and is often the default choice for general-purpose breaking. It is ideal for hard materials like reinforced concrete, asphalt and medium-hard rock.

A chisel tool has a flat, wedge-shaped tip that directs breaking force along a single line. It creates controlled breaks in concrete slabs, for splitting large rock, or for trenching in hard soil and soft rock.

The blunt tool features a flat, square face designed to transfer maximum energy across a broader surface area, so it excels at breaking softer, more brittle materials like non-reinforced concrete. It is also ideal for secondary breaking of materials already fractured by initial impacts.

Blue Diamond has made these tools easily interchangeable with minimal downtime for changing job conditions.

Built-in Features

Blue Diamond breakers incorporate numerous features that enhance durability, performance and ease of maintenance:

Blue Diamond breakers feature a solid mono-block design milled from a single piece of steel, rather than assembled sections held together with tie rods that can stretch or loosen over the life of the breaker. The design eliminates maintenance issues and costs associated with tie rod wear found on competitive breaker models.

All Blue Diamond breakers have a polyurethane shock-absorbing shell that minimizes vibration transfer to the host machine. This design protects the hydraulic components, pins and bushings from excessive wear, while also improving operator comfort.

An energy recovery system maximizes efficiency by recycling hydraulic pressure within the unit, allowing the breaker to deliver more impact energy with less hydraulic input from the host machine. This system also incorporates protection against back pressure spikes that can damage the machine's hydraulic system.

Blue Diamond breakers have only two parts: the piston and the distributor valve. This simple design reduces potential failure points, while also making field service more straightforward when maintenance is required.

An anti-blank firing system prevents the breaker from operating unless the tool is pressed against a surface, protecting internal components from damage that can occur when firing without resistance.

Support and Warranty

Here at Blue Diamond, we believe above all that we are here for our customers. That includes both the equipment dealer and the equipment owner who buys our products. Our focus is on providing customer satisfaction through responsive communication, high quality products and parts availability.

Blue Diamond offers an extended three-year warranty that demonstrates confidence in the durability and reliability of theses hydraulic breakers.

| Part Number | Model | Working Pressure | Max Oil Flow | Frequency (BPM) | Operating Weight | Tool Diameter | Energy Class | Carrier Weight | (PSI) Back Pressure |

|---|---|---|---|---|---|---|---|---|---|

| Part Number335005 | ModelHB50 | Working Pressure1,750 | Max Oil Flow7 | Frequency (BPM)1,200 | Operating Weight132 LBS | Tool Diameter1.5 | Energy Class100 | Carrier Weight1,500-2,650 LBS | (PSI) Back Pressure290-360 |

| Part Number335009 | ModelHB95 | Working Pressure1,750 | Max Oil Flow11 | Frequency (BPM)1,200 | Operating Weight220 LBS | Tool Diameter1.8 | Energy Class200 | Carrier Weight2,650-4,000 LBS | (PSI) Back Pressure290-360 |

| Part Number335016 | ModelHB165 | Working Pressure1,750 | Max Oil Flow13 | Frequency (BPM)1,200 | Operating Weight370 LBS | Tool Diameter2.2 | Energy Class400 | Carrier Weight4,000-6,600 LBS | (PSI) Back Pressure290-360 |

| Part Number335021 | ModelHB210 | Working Pressure1,750 | Max Oil Flow16 | Frequency (BPM)1,100 | Operating Weight463 LBS | Tool Diameter2.5 | Energy Class500 | Carrier Weight6,100-9,900 LBS | (PSI) Back Pressure290-360 |

| Part Number335030 | ModelHB300 | Working Pressure1,750 | Max Oil Flow21.2 | Frequency (BPM)1,100 | Operating Weight661 LBS | Tool Diameter2.9 | Energy Class700 | Carrier Weight8,800-15,500 LBS | (PSI) Back Pressure290-360 |

| Part Number335040 | ModelHB400 | Working Pressure1,750 | Max Oil Flow29.2 | Frequency (BPM)900 | Operating Weight882 LBS | Tool Diameter3.1 | Energy Class1,000 | Carrier Weight13,500-20,900 LBS | (PSI) Back Pressure363 |

| Part Number335053 | ModelHB530 | Working Pressure1,750 | Max Oil Flow32 | Frequency (BPM)900 | Operating Weight1,169 LBS | Tool Diameter3.3 | Energy Class1,200 | Carrier Weight17,650-25,350 LBS | (PSI) Back Pressure363 |