Skid Steer Brush Cutters

Whether you call it a brush cutter, brush hog, bush hog or a mower — Blue Diamond has a skid steer brush cutter for you! Blue Diamond skid steer and CTL brush cutters have been widely accepted by contractors in North America for their ability to handle site prep and clearing. Because of that success we have grown our offering – now providing Heavy, Extreme and Severe Duty models – designed to handle any job, large or small.

Skid Steer Brush Cutters

Blue Diamond Attachments offers key differentiators that add performance and value to brush cutter attachments

- All Blue Diamond brush cutters are engineered for specific applications to fit different classes of machines with different power levels as well.

- Blue Diamond has parts in stock and live support to back its products.

- Blue Diamond attachments are designed to work with all equipment brands.

- Blue Diamond ships each brush cutter ready to use, versus other options on the market where additional hoses or oils are required.

Blue Diamond brush cutter attachments come with the Blue Diamond Satisfaction Guarantee, and all are backed by a 1-year warranty.

Selecting brush cutters for skid steers

When looking at the right model of brush cutters to match with a skid steer or compact track loader (CTL), there are questions to ask based on the technical data specs, and there are more subjective questions to ask based on the type of work being performed with the attachment.

Answers to these questions will point you in the right direction for optimal success.

For instance, understanding the rated operating capacity of the machine, as well as that machine’s auxiliary hydraulic flow capabilities, get you really close to the most optimal model. The brush cutter’s weight and hydraulic requirements must be within what the loader’s capabilities.

Putting a brush cutter that is near or heavier than the machine’s lifting capacity with hydraulic flow requirements higher than the machine can provide, will lead to poor performance and dissatisfaction.

Similarly, matching a smaller brush cutter to a larger machine with higher auxiliary hydraulics capabilities will lead to potentially poor performance, as well as create working conditions that could damage the attachment and lead to downtime.

Weight

Blue Diamond brush cutters range in weight from 845 pounds up to 1,957 pounds, well within the rated operating capacity of most skid steers and CTLs.

It’s important to understand, however, that the heavier brush cutters will perform better with larger machines in terms of handling and maneuverability. We want to avoid situations where we are putting the largest, most powerful brush cutters on the smallest skid steers or CTLs.

A general note while on that topic: CTLs will generally provide a better, more consistent performance with brush cutters, as the large rubber tracks help the machine move more evenly and consistently across the surface, whereas rubber-tired skid steers are more susceptible to uneven ground causing the machine to “porpoise” – rocking back and forth unevenly over the terrain – which can cause uneven cutting.

Hydraulic Flow

The required hydraulic flow of each Blue Diamond brush cutter ranges from 14 gallons per minute up to 45 gallons per minute.

Motor sizes are paired with each cutter depending on its width and intended host machine. For instance, the Sixty-inch heavy duty brush cutter is available with two motor options to maximize efficiency with 11-16 gpm or 16-20 gpm flow ranges.

Hydraulic flow, as much as any factor, influences the perception of success and performance for a brush cutter.

If the flow rates on a machine are below the suggested range of the attachment, there is a risk of underperformance, dogging and dissatisfaction.

If the flow and pressure rates on a machine are above the suggested range of the attachment, there is a risk of blowing hoses and seals, or over-spinning the motor which will lead to failure.

Always remember that throwing as much hydraulic power at an attachment just because the machine is capable does not mean that it will lead to better performance. It can lead to dissatisfaction and costly downtime.

One great advantage of Blue Diamond Attachments’ brush cutters? Our low flow models will keep up and often outperform some of the high flow cutters on the market. This is because the hydraulic pumps that drive the machine are typically connected with the pumps that run the attachment’s auxiliary connections. Why sacrifice power to keep your machine moving when you can cut just as well or better with less flow? This also provides advantages in initial purchase price and the lifetime total cost of ownership of the attachment — there will be some situations where, comparatively, you can get more done for less.

Cutting Width vs. Total Width vs. Cover Width

Another important thing to consider is the difference between cutting width, total width and cover width.

When we talk about cutting width, we are talking about the actual swath of cutting made possible by the attachment. For instance, the seventy-two-inch severe duty model has an actual cutting width of seventy-two inches, but the total width of the attachment frame at its widest point is 77 inches. This is important to know when considering how the attachment will be transported.

When we talk about cover width, this refers to the attachment’s ability to “cover” the width of the tires or tracks. This is a general best practice as it relates machine operation – that the width of the attachment is either the same width, or slightly larger than the width of the tires or tracks. This similarly helps ensure proper sizing for trailer loading, and also helps ensure that as you’re moving forward with an attachment, you can be sure that there is enough clearance for both the attachment and the tires or tracks of the machine.

Once we’ve answered all of the technical questions, there are more subjective questions that pertain to the type of work that the cutter will be used for.

For instance, right now, you may only need to “mow” a certain area of brush a few times a year – but maybe you have a vision of adding significant brush clearing as part of your day-to-day work with larger-diameter brush. That will give you an idea as to whether you should be looking for something with a smaller cutting capacity, or something heavier like the extreme or severe duty models.

So when you look at the Blue Diamond Attachments Line-up, there are heavy duty, extreme and severe duty models to choose from. Within each of those families there are some other choices to consider — We’ve already talked about size and flow requirements, but another thing to consider is the style of cutter.

Most cutters are available with an open front or a closed front. An open front model has exposed cutting blades in the front and is going to allow you to be more aggressive in areas with larger materials. The closed front version helps contain the cut material and can result in more of a smaller final product because it stays within the cutting chamber. This model is often preferred when cutting near buildings or roadways.

Performance Categories

Blue Diamond provides eight different core models for use with skid steers and CTLs:

- Sixty-inch and seventy-two-inch heavy duty models

- Sixty-inch and seventy-two-inch extreme models

- Seventy-two inch and eighty-four-inch severe duty models

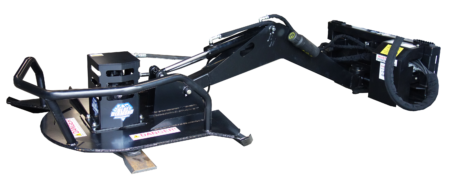

- A swing arm cutter that provides flexibility and reach for cutting on more extreme slopes of terrains where horizontal operation of a skid steer or CTL may not be possible

- And a double-motor, eighty-four-inch brush cutter

The heavy-duty Blue Diamond lineup includes our new Heavy Duty Open Front and Heavy Duty Closed Front cutters. As with all Blue Diamond Attachments brush cutters, the blades are bi-directional. Many operators will use one side of the blades for mowing and stalks, and use the other side of the blades for heavier brush cutting. The closed-front design provides a cutting capacity of up to 3 inches, while the open-front design increases cutting capacity to up to 4 inches in diameter.

The extreme-duty lineup comes in open and closed front configurations, and both are available with standard or high-flow motors. These are the most versatile brush cutters on the market, making them our most popular cutters. They handle grass easily and can cut trees up to eight inches with the high-flow models. Each model comes with double-sided heat-treated blades that are mounted on a reinforced, heavy ¾-inch thick blade carrier. The heavier blade carrier uses its weight as inertia to power through tough cuts that could stall out lesser units. The motor compartment on this design is fully enclosed to keep out debris that could cause the motor to overheat. The rear of the cutters have an open design to keep it running at peak performance. Other brands have a rear roller to carry some of the weight, but that hinders production since it will cause the material to clog and drag along.

The Blue Diamond severe duty cutters are in an elite class of their own. These come in an open-front configuration with the blades extended out the front and will take down a ten-inch tree with ease. With a cutting width of 72 inches, we have three motor options available to fit most compact track loaders. With the highly efficient radial piston motor, this cutter particularly highlights where our standard-flow model will outperform many of the high-flow models on the market – a great point for both value and performance.

This cutter means business and will tackle any job you throw at it. The four oversized double-sided blades and a massive one-inch thick blade carrier is what sets it apart. The serrated edge on the blade carrier keeps the material flowing for a cleaner finish. The integrated pressure gauge is easily visible from the operator’s cab, to ensure minimal stall-outs and keep it going at peak performance. There are also adjustable skid plates that help you adjust cutting height as you operate.

There are also two additional units in the Blue Diamond skid steer cutter lineup: the 84-inch dual motor cutter and the swing arm cutter.

The dual motor brush cutter delivers a cutting width of eighty-four inches and is really ideal for overgrown and heavy mowing applications, but can cut material up to three inches thick when used in light clearing applications. It also features adjustable wheels to set the cutting height.

Another popular model is the swing arm brush cutter. This unit puts the cutting plane on a movable arm so the operator can cut on slopes, along hedges, over low fences or barriers, and reach into places that are hard to access. A forty-four inch cutting width and 4-inch cutting capacity is the ideal size to maximize productivity while maintaining access to the tight spots. The boom can be positioned straight forward to reach up, out, or down to the target area, or turned 90 degrees to the right side when cutting outside of the width of the machine.

Built-in features

20 years of experience in the brush cutting industry has allowed us to refine our cutters to be the best in the business. The main component of a brush cutter is the direct drive. Sometimes called the “bearing housing” or “load adapter”, this component holds the cutter together and transfers the power from the motor through to the blades. It takes the impact of each cutting blow, so we have engineered our direct drives to withstand decades of use. Each drive is sized appropriately to maximize performance in each class of cutters. Other brands of cutters often utilize a cheaper gearbox instead of a direct drive, and those will simply not hold up to the rigorous demands that are required.

Another critical component of each brush cutter is the wire protection system. All of our brush cutters have a built-in guard that will make sure that the lower main seal is secure. This is very important so the bearing lubrication remains in the direct drive to keep the cutter running smoothly. If a piece of wire or thorny vine gets wrapped around the main shaft, it cannot get through to damage the seal.

The Blue Diamond cutters also feature an angled back, which allows cut material to roll out more easily and lets the cutter jump over stumps. The heavily reinforced deck is thicker, and wear bars have been added on the side skids to provide longer life when used in abrasive ground conditions.

Support

Here at Blue Diamond, we believe above all that we are here for our customers. That includes both the equipment dealer and the equipment owner who buys our products. Our focus is on providing customer satisfaction through responsive communication, high quality products, and parts availability. A one-year warranty through an authorized Blue Diamond Attachments dealer is backed by our dedicated team of product specialists.